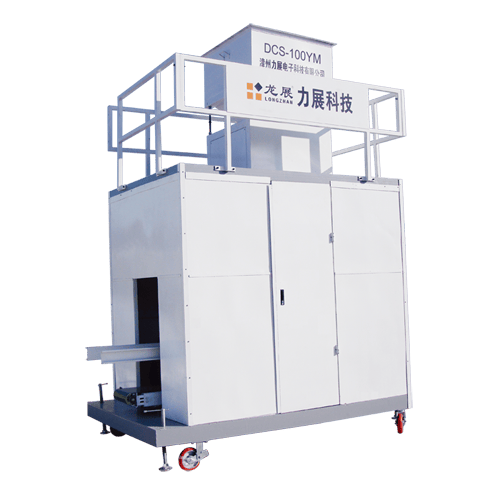

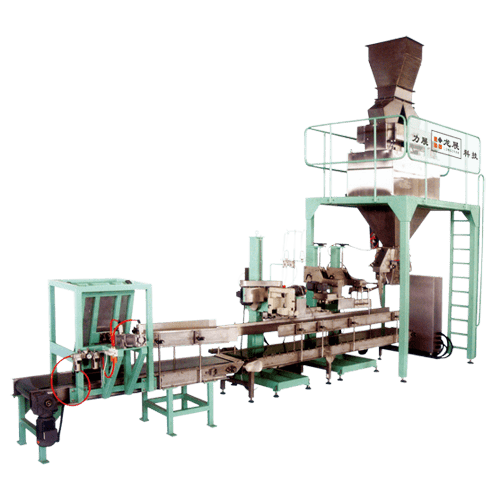

Lizhan Technology is a technological company that is specialized in the development and manufacture of electronic quantitative packaging weighers, fiberboard sizing control systems and feed mixing control systems.

Lizhan Technology devotes itself to be the pacemaker of precise small-pack quantitative packaging weighers, and we have now four series and more than 60 models of quantitative packaging equipments, which can be applicable in areas such as food, feed, chemical, food, salt, metal and other industries.