Position:Home > Vacuum packaging machine > Details

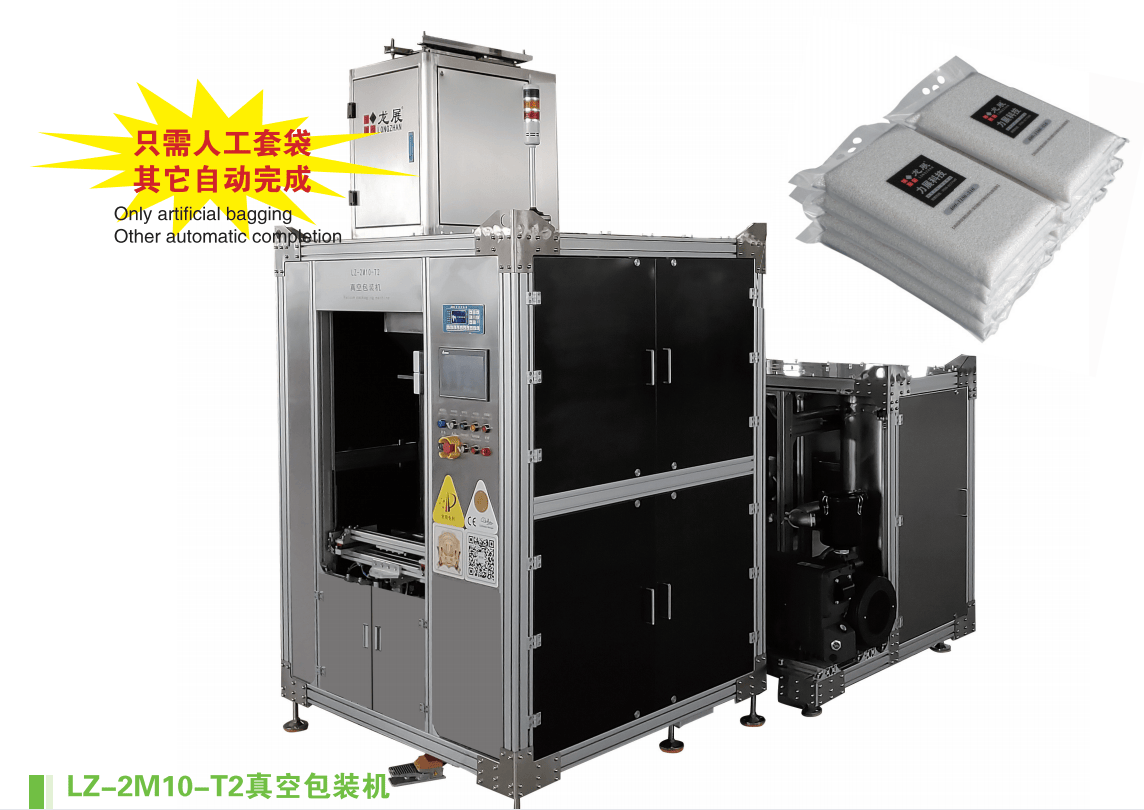

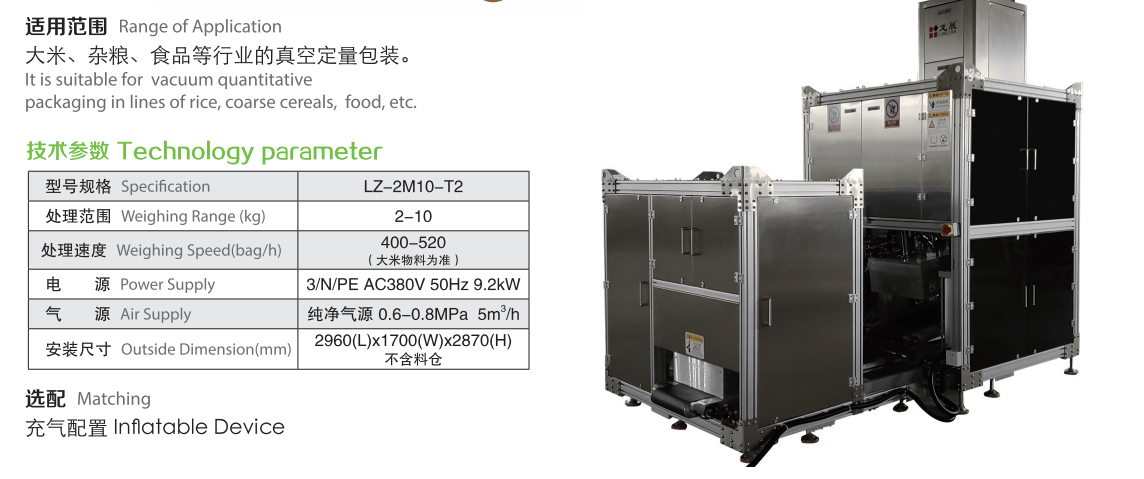

- LZ-2M10 vacuum packaging machine

-

Product features:

1.Pneumatic components are adpoted 100% German Festo, with high reliability and long service life; 2.Using low-voltage devices from Schneider France; 3.The programmable controller PLC of Germany Siemens is adopted. 4.using a special one-time sealing technology, low damage; 5.Good shaping: consistent shape, high flatness, can be controlled at 15-22mm from the seal to the tail. 6.The special constant temperature sealing process does not require thermally conductive tape, which greatly reduces the package breaking rate of the product; 7.Only manual bagging is needed, and other tasks are automatically completed by the equipment. There is no need to put materials into the vacuum link, which reduces labor intensity; 8.Optimized design, reliable work, and quick change of packaging specifications. 9.With real-time measurement and control functions such as temperature, pressure and vacuum; 10.With sound and light indication function; 11.With power failure parameter protection function; 12.Quantitative control instrument with parameter backup and restore function; 13.The whole machine adopts high standard stainless steel material to ensure that the production meets the requirements of sanitary standards;

Automatic complement:Artificial bag→ weighting → filling → forming → vacuum extraction → heat sealing → bag unloading → feeding