Position:Home > Electronic scales > Details

- DCS-50GZ Electronic Quantitative Weigher

-

Product features:

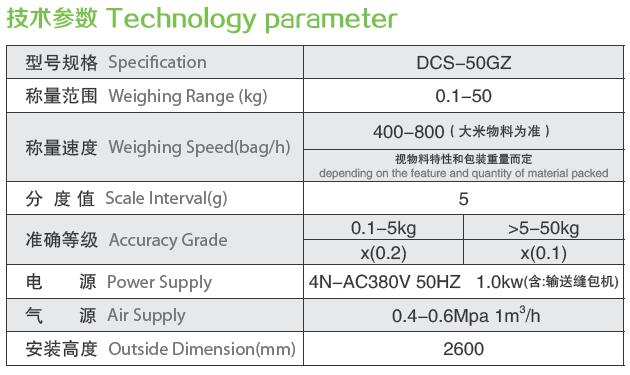

1.High degree of user-friendliness: Various parameters can be set according to user needs, automatic alarms for out-of-tolerance, power failure parameter protection functions to meet new control functions, quantitative control instruments with parameter backup and recovery functions, etc. RS232 / 485 communication interface is reserved, which can be connected to the production management system at any time; 2.The multi-stage combined feeding method can be used to achieve 21 modes of feeding in 6 modes, and the size of the feeding port can be adjusted, which increases the feeding speed of the large package and achieves the accuracy of the large package.because the vibration feeding plane is adopted,so the speed of small packaging is fast and accurate; 3. Instrument control: It adopts German B.L weighing technology chip, which can convert 360 times per second, fast speed and long service life; 4.Pneumatic components are 100% German Festo, with more stable quality and longer life; 5.The conveyor adopts a custom sewing head, the first domestic optical fiber sensing technology, automatic sewing and automatic thread cutting, the length of the thread head is controllable, and manual sewing can be achieved. Frequency conversion speed regulation ensures that the suture is flat and beautiful; 6.using "arm-type" alloy steel material, long life; 7.Wide packaging range and fast speed: It can achieve a packaging range of 0.1-50 kg / bag, and the weighing speed can achieve 400-800 bags / hour. It is currently the widest weighing range, the fastest speed, and the accuracy of domestic single-body scales. The highest device. 8.Contact with materials is made of stainless steel to ensure that production meets the requirements of hygienic standards.